Nearly 2,500 years ago, Socrates (when he was not occupied with founding Western philosophy and instructing his star student, Plato) pioneered a method of asking questions that led people to draw conclusions and pursue deeper truths and realities. His practice of relentlessly picking apart ideas earned him the deserved reputation of being the gadfly of philosophy. His technique, however, had real genius behind it. The goal of probing an idea with repeated questions was not just to get information. It was intended to persistently follow threads, look for contradictions, and help build consensus for the conclusions.

In an earlier blog, I mentioned a technique known as the 5 Whys that has a lot in common with Socrates’ approach, and it bears exploring further. Project managers can make great use of this when we need to get to the bottom of an issue or a problem.

I have always maintained that there are easier ways to make a living than project management. We have a tough assignment. We’re expected to solve business problems, oftentimes before the problem is actually defined or understood, and this is not always easy to do.

The good news is that when issues or problems arise, we have an arsenal of tools at our disposal, including Root Cause Analysis (RCA), Ishikawa/fishbone diagrams, Management Oversight Risk Trees (MORT), and others. These techniques are intended to be systematic and rigorous, but there is another one that is fairly lightweight and easy, and almost anyone can use it with just a little practice. Sakichi Toyoda, the father of the Japanese Industrial Revolution and founder of Toyota Industries, pioneered a technique knows as the 5 Whys, and while it might not have been directly inspired by Socrates, it would certainly have made him proud.

The way the 5 whys technique is used in real life is to look at a problem, ask why, and then repeat with the answer you are given. It takes some practice, but once this technique is mastered, it becomes a management favorite. In fact, when you get really adept at it, people may not actually realize you are employing it.

As I have grown to really appreciate this technique, here are a few tips for successfully employing the 5 Whys the next time you need to dig more deeply into a problem.

1. Do not ask all the 5 Whys at once

When my oldest son was very young, he loved asking questions, and regardless of my answer, the next question out of his mouth would be “why?” As an earnest and well-intended young parent, I initially tried to give him legitimate answers, but after a while, children wear you down to the point where you just seek to stifle the conversation. Example:

Me: “Don’t stick your finger in the power outlet.”

Son: “Why?”

Me: “It can hurt you.”

Son “Why?”

Me: “Well, it has to do with the fact that there are free electrons stored in the copper and your finger is acting as a conductor, allowing them to flow… er… just because.”

The point of this is that you might encounter more success if you do not pepper others with all five whys at once. Find a way to spread them out, and ask a variety of people. Stakeholders will feel less like you are on an inquisition and will open up more readily.

2. Don’t get discouraged

It is important to remember that people often resist getting to the root cause, and they often are not even aware they are resisting. Instead, they simply get more uncomfortable the closer you get. This may have to do with the fact that getting to the root cause can lead to change and upheaval, and many people are very uncomfortable with change.

When you start encountering pushback, continue to press in, but try to soften your technique.

3. Beware of false positives

People can become very certain about things that are not necessarily accurate. Not that long ago in our history, doctors were “sure” that yellow fever was caused by “bad air.” The same was true for malaria (the name literally means “bad air”). While there were correlations between these diseases and swampy, damp air, it was actually mosquitos that were transmitting them.

In project work, you may have stakeholders who are confident that one problem is the root, when a deeper problem may be to blame. Resist the temptation to latch onto the first plausible answer that is given.

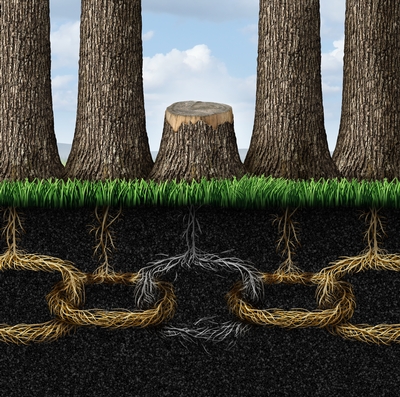

4. Look at processes too

Many times it is our organizational processes themselves that are broken. Years ago an auto manufacturer had a famously expensive auto recall. In the aftermath, blame was assigned to a number of causes before the 5 Whys technique was used to get to the real root. It went something like this:

Problem: Expensive recall due to defects in the door

- Why – The door hinge is failing

- Why – The steel is fatiguing at a stress point

- Why – The door weight changed during design, but the hinge was never redesigned

- Why – We changed engineering staff halfway through the process

- Why did that matter?

Conclusion: The process itself needs updating, and our design workflow needs to be more robust.

It’s often the processes themselves that are at the root of issues.

5. Follow the incentives

The essayist, H. L. Mencken, famously quipped “When somebody says it’s not about the money, it’s about the money.” Basic economic theory dictates that groups of people generally behave rationally. In other words, they behave in the ways they are motivated to behave.

Many times you can use the 5 Whys technique to follow an incentive trail back to the problem.

Here’s an example:

Issue: The project team has missed their third consecutive deadline.

- Why – Team estimates have consistently been too optimistic

- Why – Sales has put organizational pressure on the team to bid more aggressively

- Why – It is easier to get a change order after the initial contract has been signed than it is to negotiate it at the beginning

- Why – Sales is working too hard to close the deal up front without regard to the downstream effort and delivery.

- Why – Sales’ compensation plans are not aligned with corporate goals.

Conclusion: The organization needs to bring sales closer to delivery and change the way commissions and compensation plans are structured.

But as Upton Sinclair observed that “It is difficult to get a man to understand something when his salary depends on his not understanding it.”

Most people are not intentionally deceptive. It is that things look different from different perspectives, and people usually orient themselves to a perspective that is most comfortable for them. Convincing them to move requires persistence, objective data, and sometimes organizational pressure.

Not long ago, an incentive problem was demonstrated in the metro area where I live. An elaborate scheme developed where employees of the public rapid transit system would skip a day of work allowing a coworker to work a second overtime shift at 1.5x the pay. Then the two would coordinate a swap, allowing the original person to make 1.5x in overtime. By diligent application of this method, employees working 40 hours were earning far more than 40 hours pay, and overall payroll costs were soaring as a result and safety concerns were becoming paramount.

The incentive path pointed the way to a broken system that had to be changed.

6. Relentlessly pursue simplicity and clarity

Antoine de Saint-Exupery once said, “Perfection is achieved, not when there is nothing more to add, but when there is nothing left to take away.” As you employ the 5 Whys, work to strip away layers of complexity, obfuscation, and excuse-making to get to the root cause of a problem.

With a little bit of practice, the 5 Whys can become second nature to you and will be a valuable tool to use to solve project problems and streamline processes.

Give us an example of how you employ the 5 Whys.